Polished and grinding materials

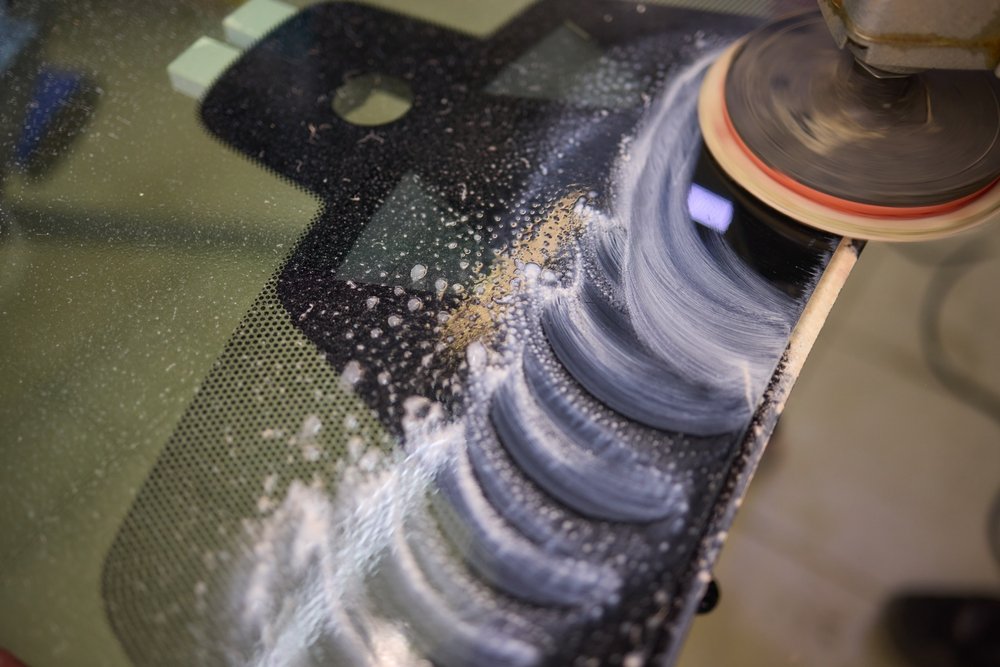

Lite New Materials is one of the professional polishing and grinding materials manufacturers in China, offering polishing & grinding materials in various fields. Provides polishing and grinding materials in glass, precision hardware, semiconductors and other fields to solve various polishing pain points for you

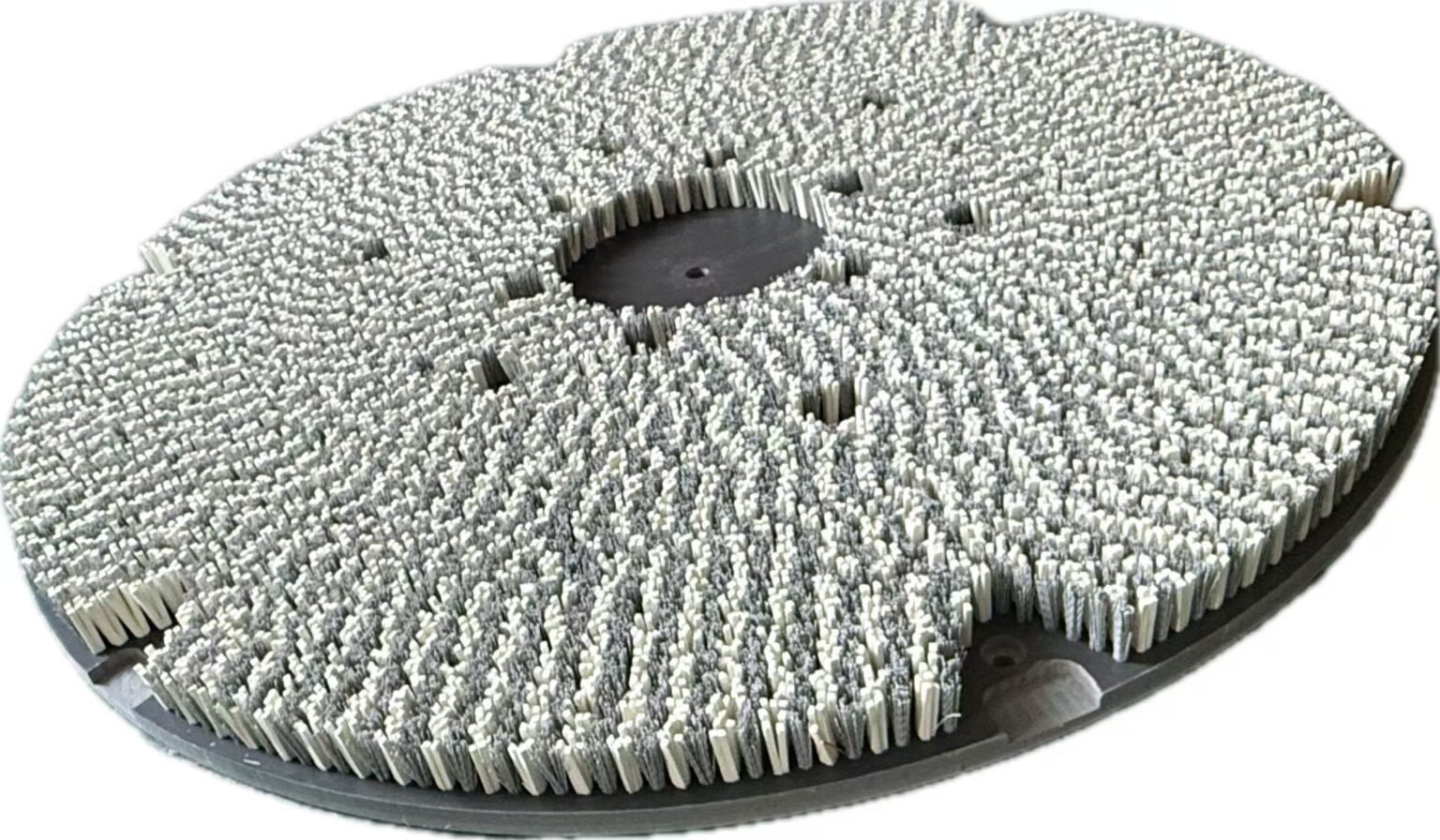

Polished brushes

Polished rollers

Polyurethane leather polishing

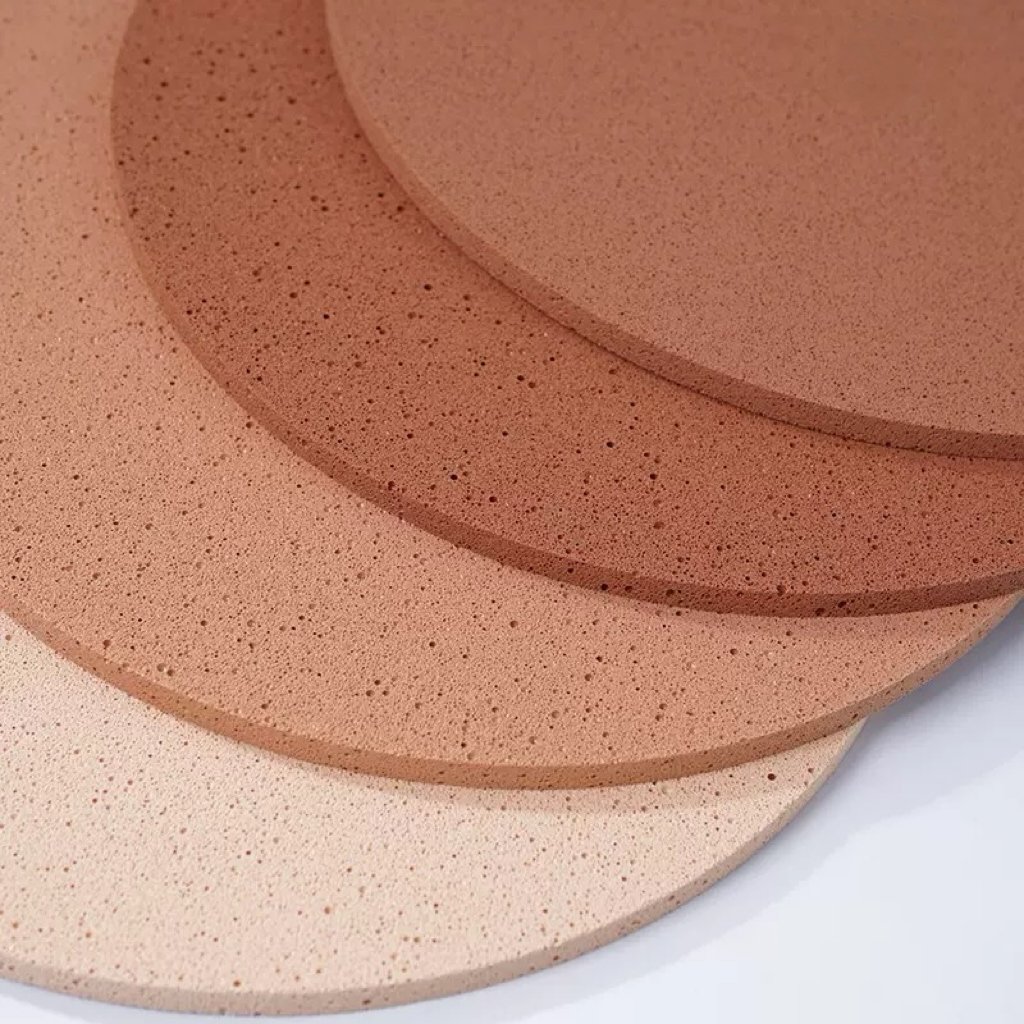

Final polishing pad

Diamond grinding pads

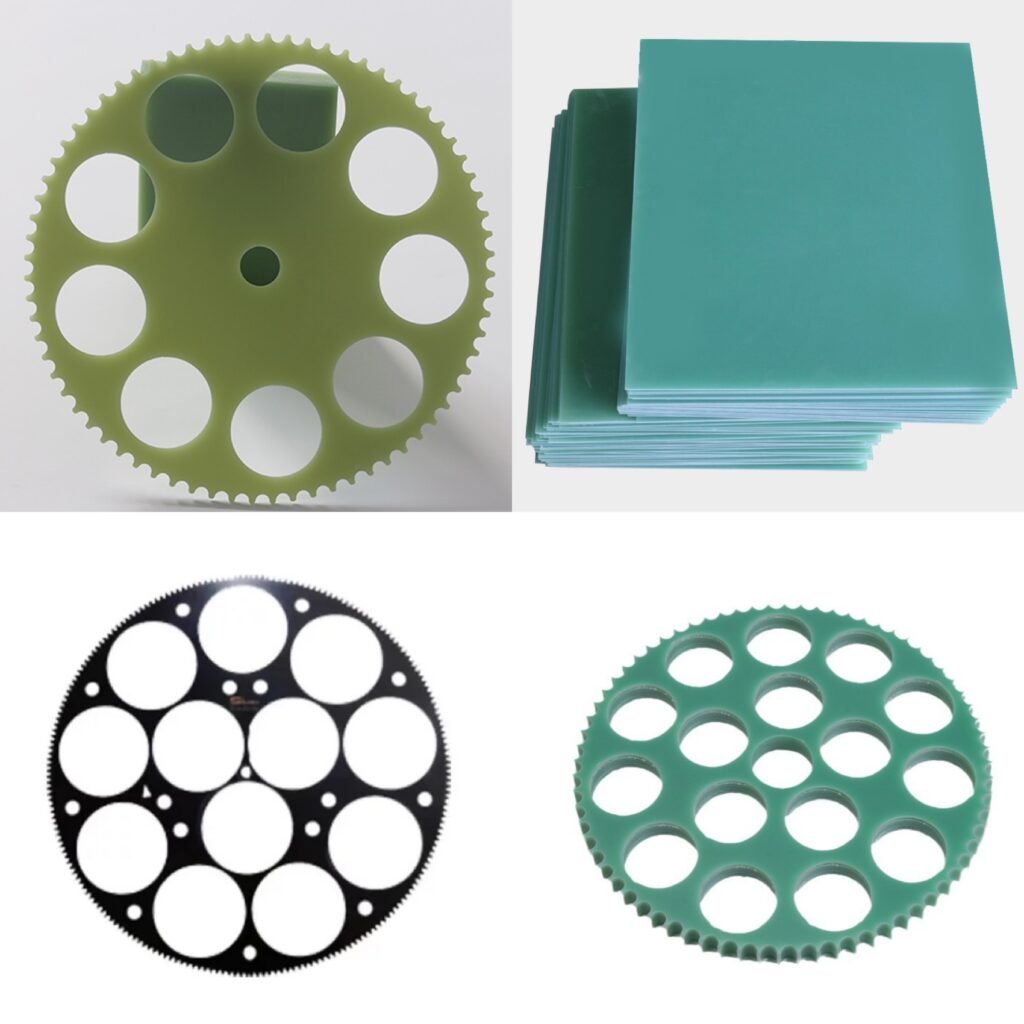

Wear-resistant Star Cruiser

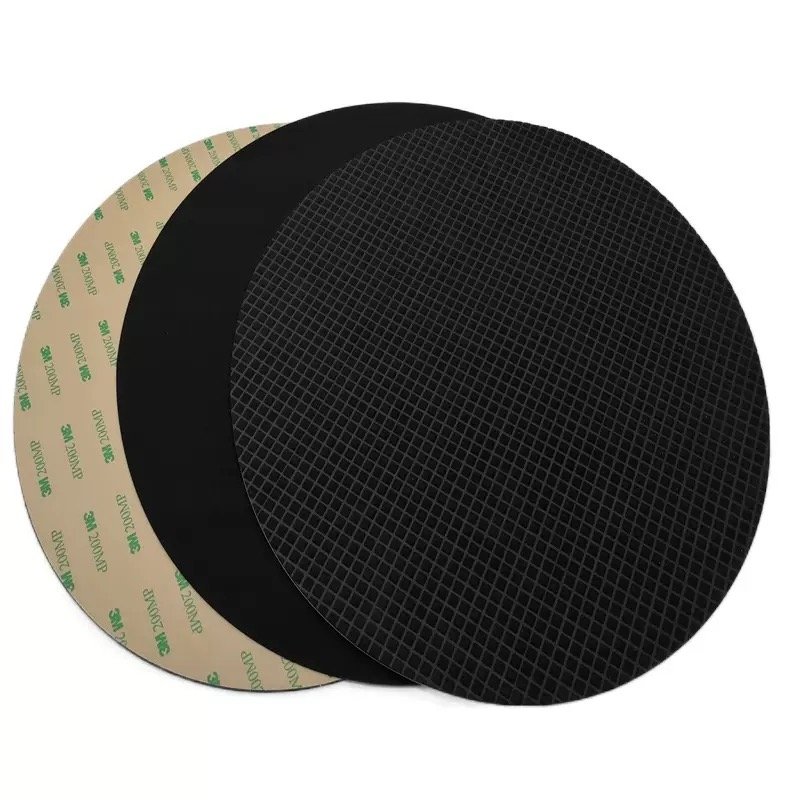

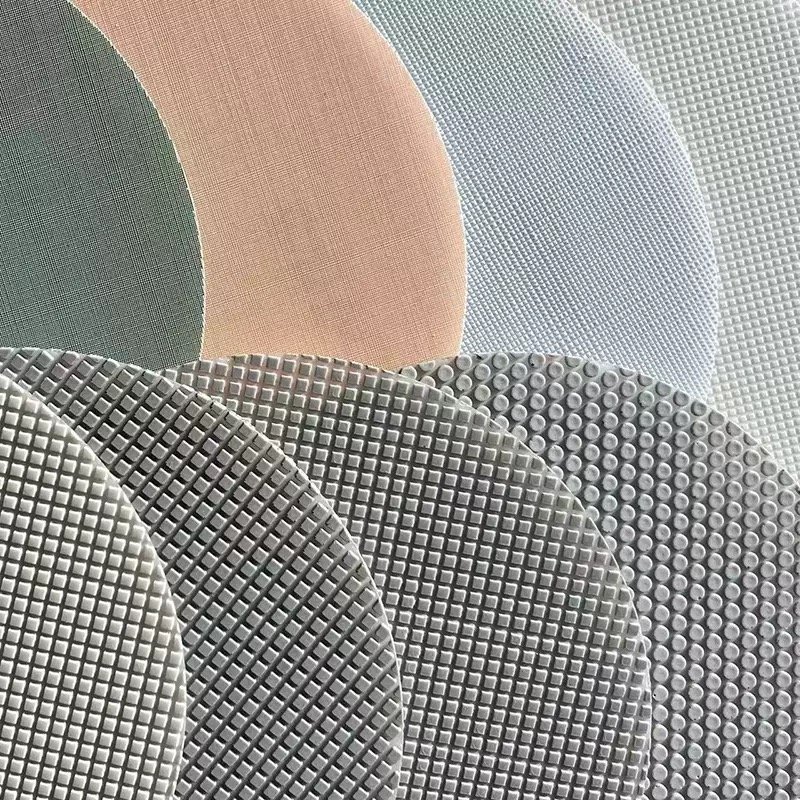

Polished blanke

Sand stripes

Get all our catalogs in one click

Customize polishing and grinding materials to your needs

Our company in the field of glass, ceramics, sapphire, precision hardware polishing and grinding continuously deep, can provide customers with a variety of polishing and grinding pain points, please tell us, we will do our best to provide you with the products you envision.

Lite polishing and grinding experts

We are a professional manufacturer of polishing materials in China because we are good at what we do. With Lite New Materials, you won’t just be treated as an ordinary transaction. We treat our customers as partners and are committed to providing quality service to ensure your satisfaction. Our polishing and grinding materials involve polishing and grinding of glass, sapphire, precision hardware, semiconductor and other fields. Our products are manufactured following strict quality protocols, ensuring that every detail meets our meticulous standards. This is the guarantee of Lite New Materials. Work with your trusted manufacturer of polishing materials. Contact us.

Advantages of polishing abrasive materials include

Efficient blemish removal: Quickly remove surface scratches, oxide layers and burrs to improve workpiece finish.

Uniform polishing: ensure that the surface of the material is uniform and fine, enhance the aesthetic and feel.

Wide applicability: Suitable for metal, plastic, ceramic and other materials, strong flexibility.

Improve performance: Reduce friction resistance, extend component life and optimize functionality.

Easy to operate: it can be matched with mechanical or manual tools to adapt to different precision requirements and improve processing efficiency.

The core difference between grinding and polishing

Grinding: In the roughing stage, high-hardness abrasives (such as diamond, silicon carbide) are used to quickly remove the material, forming an initial flat surface, but leaving a sub-surface damage layer.

Polishing: The finishing stage where a nanoscale surface finish is achieved by soft abrasives (such as cerium oxide, silicon dioxide) or chemical mechanical polishing (CMP), eliminating sub-surface damage.

Why polishing and grinding processing is essential?

Polishing and grinding materials are essential in industrial manufacturing and daily life, mainly due to their irreplaceable role in improving product performance, aesthetics and functionality. It is not only a “beautification tool”, but also a core technical link to ensure product quality, function and reliability in modern manufacturing. From microelectronics to heavy machinery, its breadth of applications and irreplaceability have established its central position in the industrial chain

Get an instant quote for your polishing materials now

Get a quote today or tell us your needs and we will get back to you as soon as possible!